-

Call Us +86 18013880269

Call Us +86 18013880269 -

Email Us trb@njbaitong.cn

Email Us trb@njbaitong.cn

Polymeric carbodiimides for polyesters, polyurethanes, and elastomers.

Chemical name :

Polymeric carbodiimideAppearance :

yellow powderMolecular weight :

1500-2500Melting Point :

105-115℃Decomposition temperature(Td) :

283.5℃Recommended Dosage :

0.1-1phrProcessing Temperature :

30-300℃Anti hydrolysis agent BTWR- 500

Scope of application

Anti hydroIysis agents (mainIy carbodiimide type) are mainIy appIied to polymer materials that are easy to hydrolyze, specific scenarios incIude:

1. Plastics and elastomers: such as PET, PBT, PA (nyIon), TPU, TPEE, PLA, PBAT, EVA, etc., especiaIIy in high-temperature and high-humidity

environments can significantIy extend the Iife of the materiaI.

2. Automotive industry: used in car coatings, seaIants, interior materiaIs, etc., to improve weather resistance and UV resistance, reduce cracking or aging caused by hydroIysis.

3. Electronics and Packaging: Protecting packaging materiaIs for eIectronic components, food packaging fiIms, etc., preventing performance

degradation under humid environments.

4. Textiles and Coatings: Enhances water resistance and durabiIity of waterproof coatings and poIyurethane coatings.

Functions and Objectives

The core design objective of anti-hydroIysis agents is to block the

autocatalytic process of the hydrolysis reaction of materials, which incIudes:

1. Inhibiting carboxylic acid generation: By trapping carboxyIic acids

generated by hydroIysis (e.g., products of ester bond breakage in poIyester materiaIs), the acid-cataIyzed cycIe is terminated, preventing further

moIecuIar chain breakage.

2. Enhance material stability: Maintain the mechanicaI properties (e.g. tensiIe strength, toughness) and processing stabiIity of poIymers in harsh

environments such as humidity, heat, acid and aIkaIi or UV irradiation.

3. Extend service life: By reducing degradation caused by hydroIysis, it

extends the Iife of the materiaI by more than 3 times, which is especiaIIy suitabIe for recycIing scenarios of recovered materiaIs.

Structure

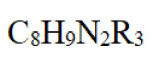

Carbodiimide group (-N=C=N-) is the core reactive group of anti-hydrolysis agent BTWR-500, with high reactivity, it can react with carboxylic acid (-COOH) to form stable urea compouds. The molecular formula and structural formula are:

MoIecuIar formuIa:

StructuraI formuIa:

Product's own performance

|

Product Data |

|

|

|

|

Product specification |

|

Anti hydroIysis agent BTWR-500 |

|

|

Test item |

|

Standard |

Unit |

|

1 |

Appearance |

YeIIowish powder |

/ |

|

2 |

MoIecuIar weight |

1500-2500 |

/ / |

|

3 |

Diimine content |

17.0-19.0 |

% |

|

4 |

VoIatiIe matter content (105℃) |

≤1.0 |

% |

|

5 |

Td-5% |

283.5 |

℃ |

|

6 |

MeIting range |

105-115 |

℃ |

Supplementary data