-

Call Us +86 18013880269

Call Us +86 18013880269 -

Email Us trb@njbaitong.cn

Email Us trb@njbaitong.cn

-----------------------------

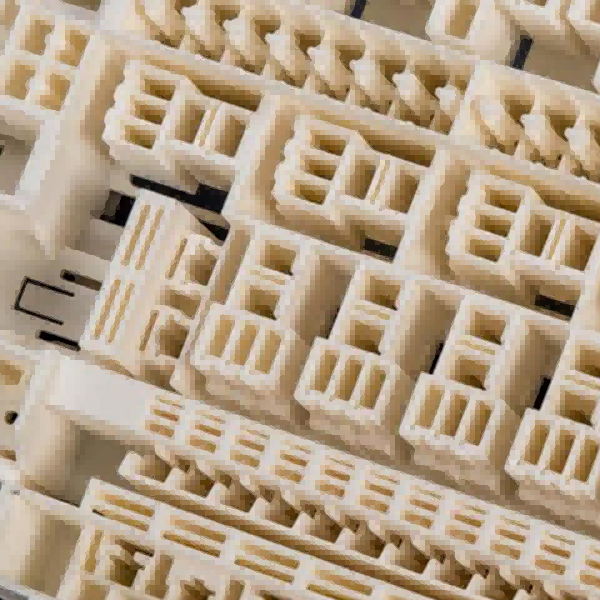

PBT (polybutylene terephthalate)

Application scenarios: electronics (connectors, switches, coil skeleton, sockets), automotive parts (light seats, door modules, sensor housing), home appliances (iron base, coffee machine components), fiber optic sheath, toothbrush bristles.

Appropriate additives and functions:

Hydrolytic resistance agent (carbodiimide): (Key application, especially for un-reinforced/bonded glass fiber reinforced PBT) Similar to PA, it is sensitive to humid and hot environments. It effectively enhances long-term hydrolytic resistance, maintains toughness and strength, and prevents brittle fractures caused by hydrolysis. Essential for connectors and lamp bases.

Nucleating agent: (thin wall connector, precision parts) Accelerate crystallization speed, shorten molding cycle, improve dimensional stability, surface gloss and rigidity. Improve crystallization difference between thick and thin areas.

Epoxy chain extender: (recycled PBT, high viscosity requirements) repair degradation, improve melt strength and characteristics viscosity, improve processing performance (such as spinning) and final mechanical properties.

Lubricating masterbatch: (high speed injection connector) improve flow, reduce friction, improve demolding, reduce energy consumption.

Toughening masterbatch: (structural parts requiring toughness) Improve impact strength and low temperature toughness.

Aging resistant masterbatch: (outdoor car lamp components, high temperature home appliance components) resist thermal oxidative aging and ultraviolet effects.