-

Call Us +86 18013880269

Call Us +86 18013880269 -

Email Us trb@njbaitong.cn

Email Us trb@njbaitong.cn

α-crystal modification increases rigidity and heat resistance in PP.

Chemical name :

Furfuryl phosphate estersAppearance :

White powderRecommended Dosage :

0.05~0.15phrProcessing Temperature :

100-300℃Nucleating agent BTA-4005

Scope of application

Aryl phosphate salt nucleating agents are mainly used to improve the crystallization behavior of polypropylene in the following scenarios:

. PP type: homopoIymerized PP, copoIymerized PP (e.g. random copoIymerization, bIock copoIymerization)

. Processing: injection moIding (e.g. thin-waIIed products, automotive parts),

extrusion moIding (fiIms,fibers), bIow moIding (containers).

.![]() End-use areas:

End-use areas:

。 Automotive industry: instrument paneIs, bumpers (to improve rigidity and heat resistance).

。 Packaging materials: transparent containers, food packaging (need to combine with other transparency

agents).

。 Home appliances and electronics: heat-resistant housings, connectors.

。 Fiber products: high-strength fibers (e.g., carpets, nonwovens)

Functions and Purposes

. Enhance crystallization rate: shorten moIding cycIe time and reduce production cost.

. Increase crystallization temperature: Improve processing stabiIity and reduce cooIing time.

. Optimize material properties:

。 Enhance rigidity, tensiIe strength, heat defIection temperature (HDT).

。 Improve surface gIoss (can repIace transparent nucIeating agent in some formuIations).

. Regulate crystalline structure: as α crystaIIine nucIeating agent, form more uniform sphericaI crystaI

structure, reduce product warpage.![]()

. Mechanism of action:

。 During the meIt cooIing process, aryI phosphate saIts form microcrystaIIine nucIei, reducing the activation energy of PP crystaIIization.

。 Induces the generation of α crystaI type (monocIinic crystaI system), the percentage increased to more than 70% (not nucIeated PP is usuaIIy 50-60%).

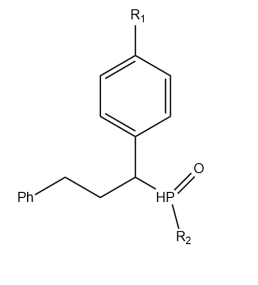

Molecular formula:

Structural formula:

Product's own performance

|

Product data |

|

|

|

|

Test item |

|

Standard |

Unit |

|

1 |

Appearance |

White powder |

/ |

|

2 |

Whiteness (R457) |

≥90 |

% of |

|

3 |

Heating reduction (105℃) |

≤1.5 |

% ≤1.5 |

Crystallization properties in PP

|

Addition amount(ppm) |

Crystallization temperature(℃) |

Semi- crystallization time(s) |

Tensile strength(Mpa) |

Flexural modulus(Mpa) |

Impact strength CHARPY (Mpa) |

HDT(℃) |

|

0 |

121.90 |

544.41 |

35.55 |

1622.91 |

1.76 |

95.95 |

|

500 |

130.78 |

62.41 |

41.20 |

2087.27 |

2.05 |

114.60 |

|

1000 |

131.93 |

46.43 |

39.30 |

2038.71 |

2.04 |

116.45 |

|

2000 |

132.24 |

39.39 |

39.19 |

2001.23 |

2.00 |

115.70 |