-

Call Us +86 18013880269

Call Us +86 18013880269 -

Email Us trb@njbaitong.cn

Email Us trb@njbaitong.cn

--------------占位---------------

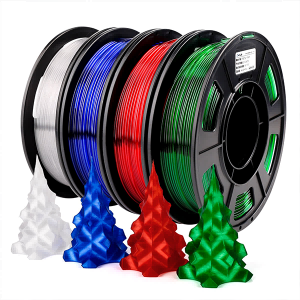

PETG (polyethylene terephthalate-1,4-cyclohexanedimethanol ester)

Application scenarios: transparent sheet/plate (signage, display stand, medical packaging), blow molding/injection molding bottles and cans, cosmetic packaging, 3D printing wire, medical devices.

Appropriate additives and functions:

Hydrolytic resistant agent (carbodiimide): (long-term use or application in hot and humid environment) Although PETG is more resistant to hydrolysis than PET, it can provide additional protection when required for long-term reliability (such as medical devices, long-term outdoor use) or in hot and humid environment.

Nucleating agent: (usually not applicable) PETG is an amorphous material, non-crystalline, generally no nucleating agent is required.

Epoxy chain extender: (recycled PETG, high viscosity applications such as 3D printing) repair degradation, improve melt strength and characteristics viscosity, improve melt stability and interlayer bonding force (3D printing), improve mechanical properties.

Lubricating masterbatch: (extrusion, injection molding) improve processing fluidity, reduce precipitation, improve product transparency and surface finish.

Aging resistant masterbatch: (Outdoor application, prevent yellowing) Resist UV-induced yellowing and slight degradation, maintain high transparency and beauty. Important for light/transparent products.